Innovation for assembly lines with Lexium™ MC12 multi carrier

Thanks to the Lexium MC12 multi carrier, ATS and Schneider Electric collaborate on a highly innovative project for an assembly line for an automotive component

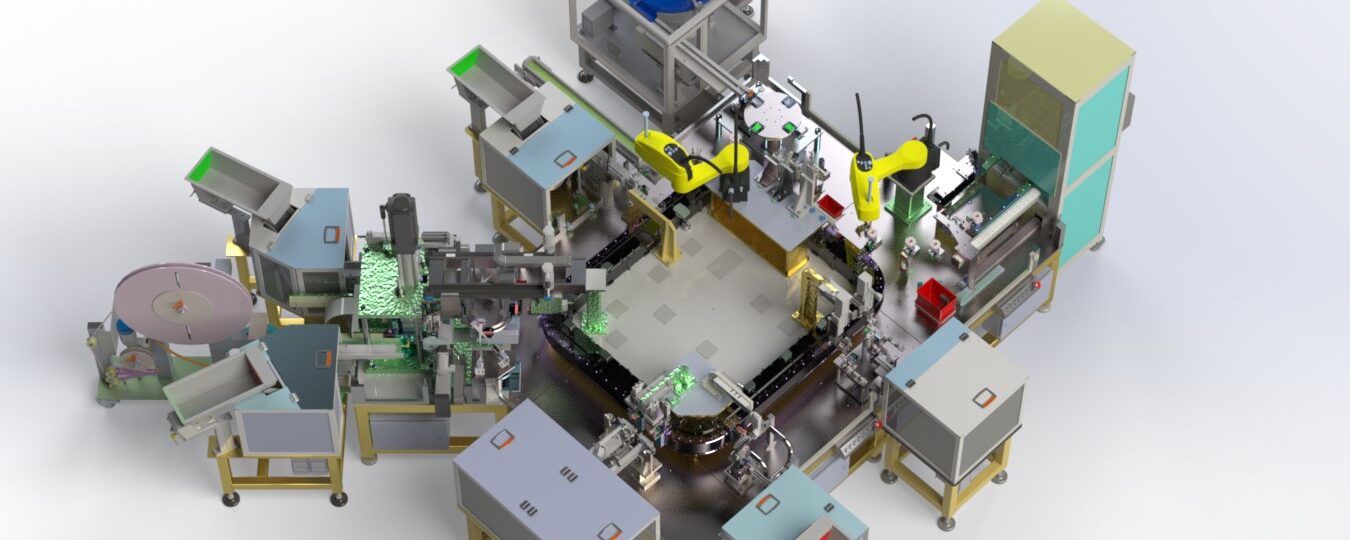

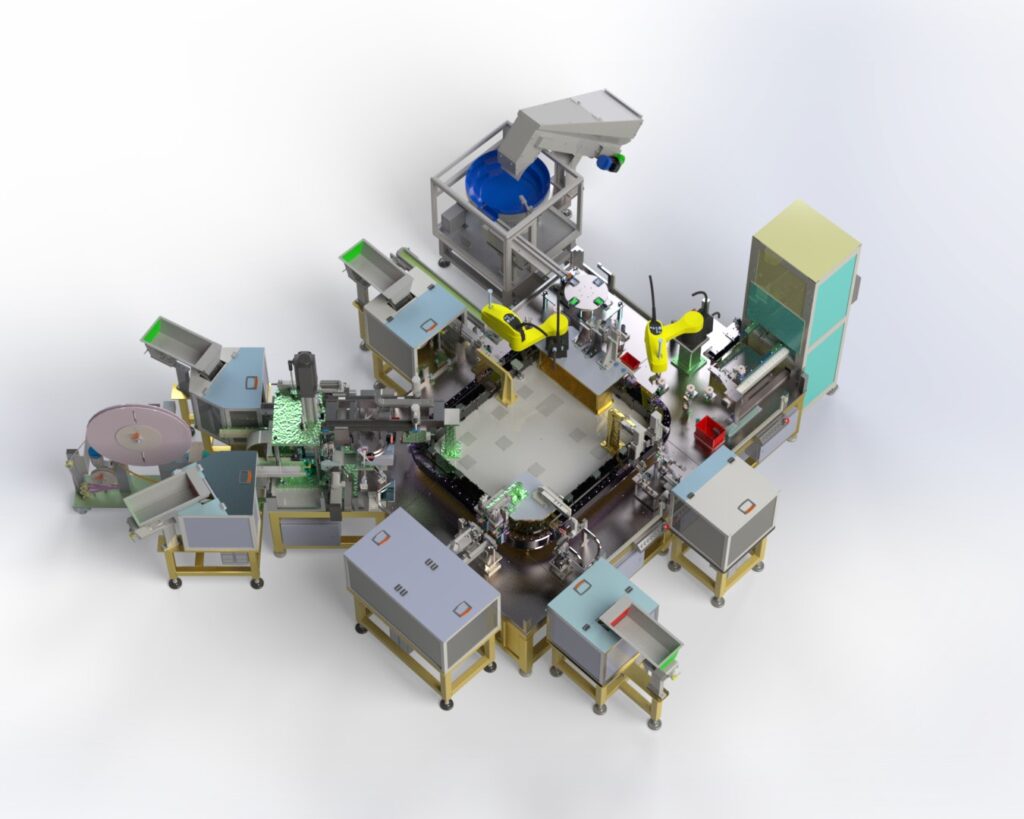

ATS is able to propose totally customized automation solutions with an approach that always aims to use the most innovative possibilities offered by technology. An example of this is the project currently underway for a customer in the automotive world, interested in the creation of an assembly line for the production of an electromechanical subassembly for parking brakes intended for cars.

To the initial request of the customer, who was thinking of a traditional system, ATS responded by proposing an alternative that exploits the technology of Lexium MC12, a multi-carrier solution developed by Schneider Electric which is characterized by flexibility in all applications involving transport and handling.

In this case, it was a question of creating the best solution for the various operational steps necessary for the assembly of the product, obtaining greater speed and maintaining the necessary ergonomics and practicality for the action of the operators during maintenance operations.

A highly innovative project for automotive components

Using Lexium MC12 ATS has proposed a project that reduces the surface area to approximately 33 m2, compared to the 42-44 expected from the adoption of “standard” technologies. Compactness is always appreciated by customers in their production spaces, and it was possible to achieve it thanks to an innovative layout, which takes advantage of the MC12’s ability to apply stations “on curves”. Three of the twelve workstations are in fact located on three of the available curves, without compromising accessibility to the stations/equipment for maintenance needs.

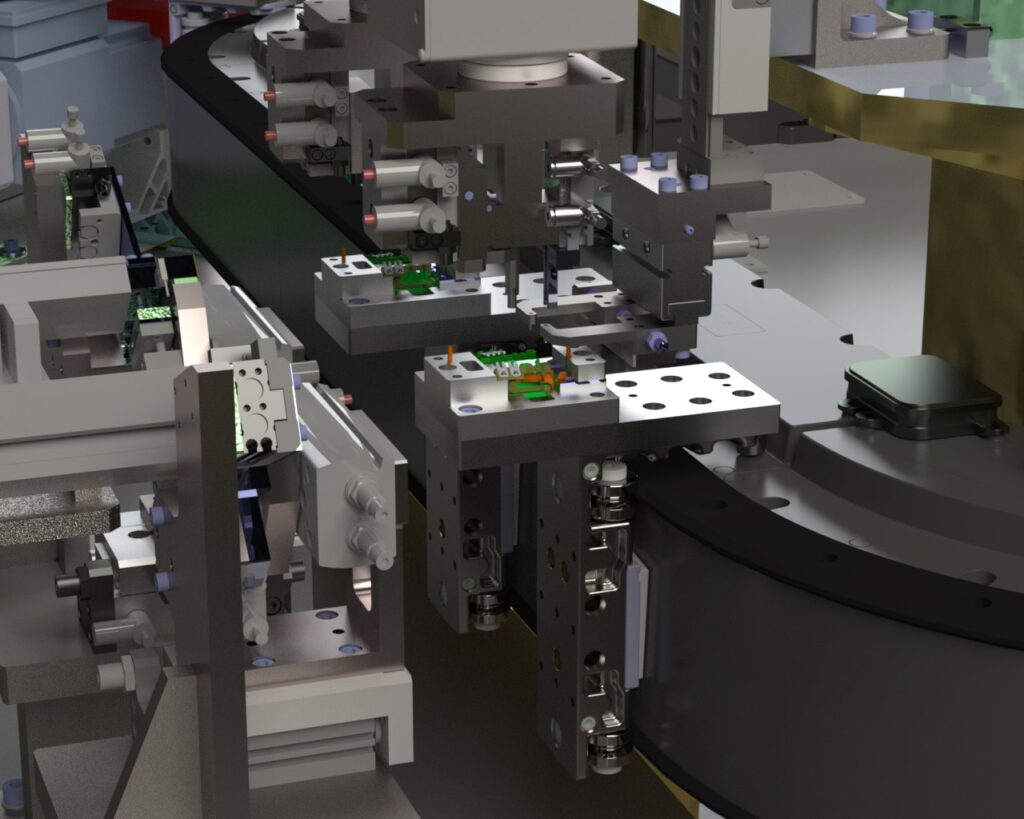

Lexium MC12 transports the component being assembled by translating it according to a layout composed of straight and curved sections that can be assembled according to process needs; it reduces the time/cycle by optimizing the entry and exit times from the station and it is a self-centering system, which guarantees high repetitiveness – so as not to require further repositioning. Once the piece arrives at the workstation, it can be worked immediately. Again thanks to the flexibility for complex movements allowed by the Lexium system, it is also possible to mount two elements (springs) one on the right and one on the left of the central body of the piece in a single station. This on a traditional setup would have required two separate stations.

“We confidently choose Schneider Electric automation technologies when they are suitable for the projects we develop for the partnership-based approach, which supports our innovation strategy: we compete on the market with competitors much larger in size than ours, focusing on the versatility that we we can offer, thanks to our more agile structure, and on the propensity to invest to integrate new generation solutions into the machines we offer, when we believe that this can bring real added value”

Read the complete article here