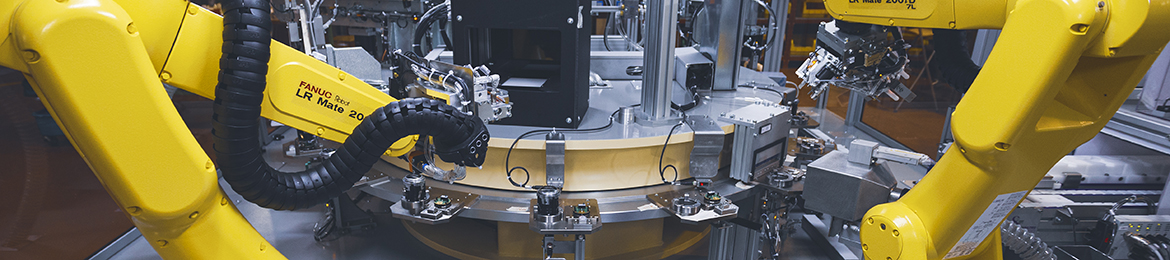

DESIGN

The Engineering Department of ATS performs all stages of mechanical design in-house. 35 years of experience and over 3,200 orders filled have resulted in substantial know-how.

The design process begins with a preliminary analysis, which entails identifying the objectives set out in the Customer’s technical specifications. Project engineering stems from the cooperation between ATS and the Customer.

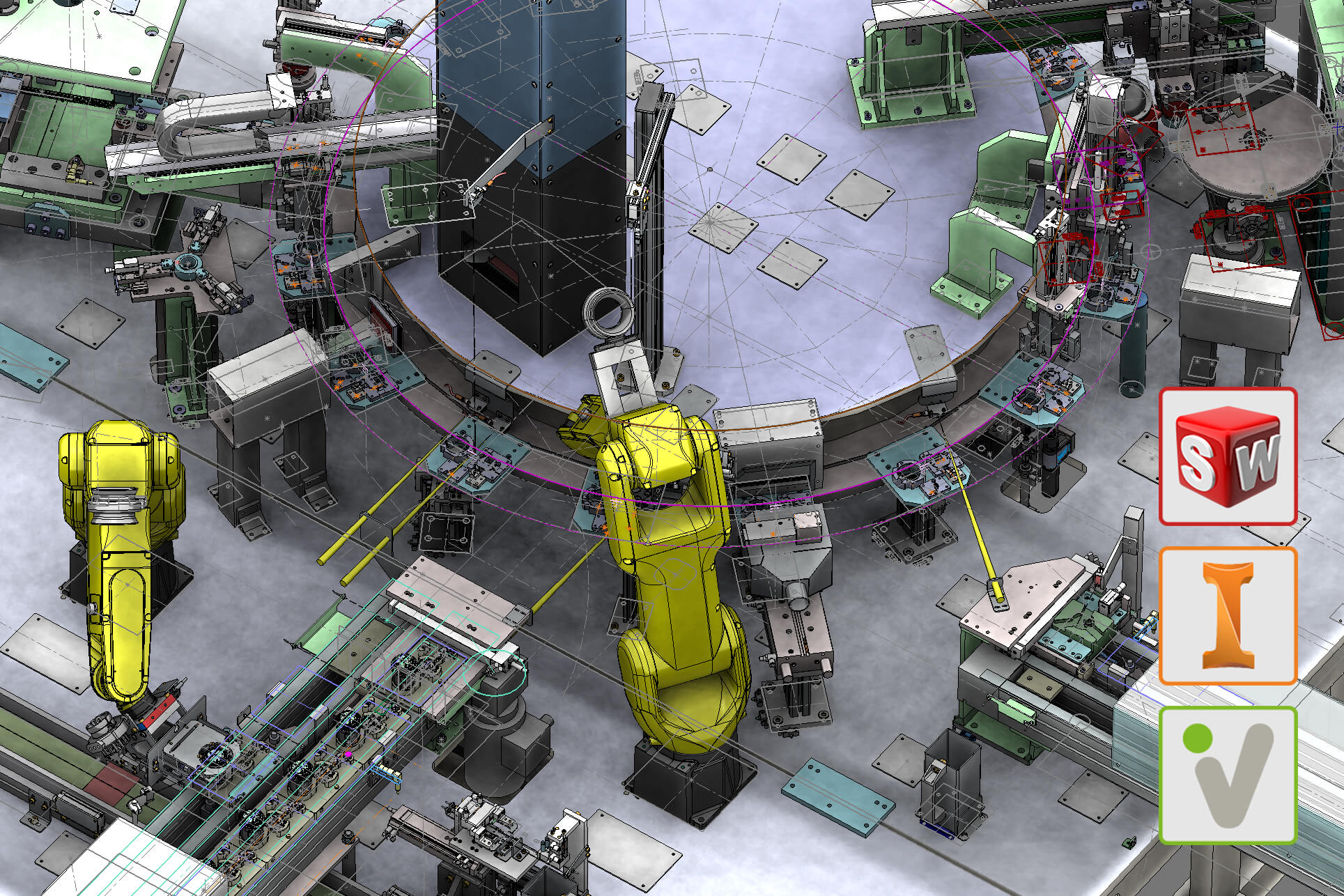

The Engineering Department of ATS is an actual research laboratory, where all design stages are analysed in minute detail through the most sophisticated 3D CAD software (SolidWorks – Inventor – VISI). For certain jobs, ATS is also supported by specialised external firms, which always work in synergy and under the supervision of ATS technical personnel.

All the machines designed and developed by ATS comply with the most current applicable European standards in force.

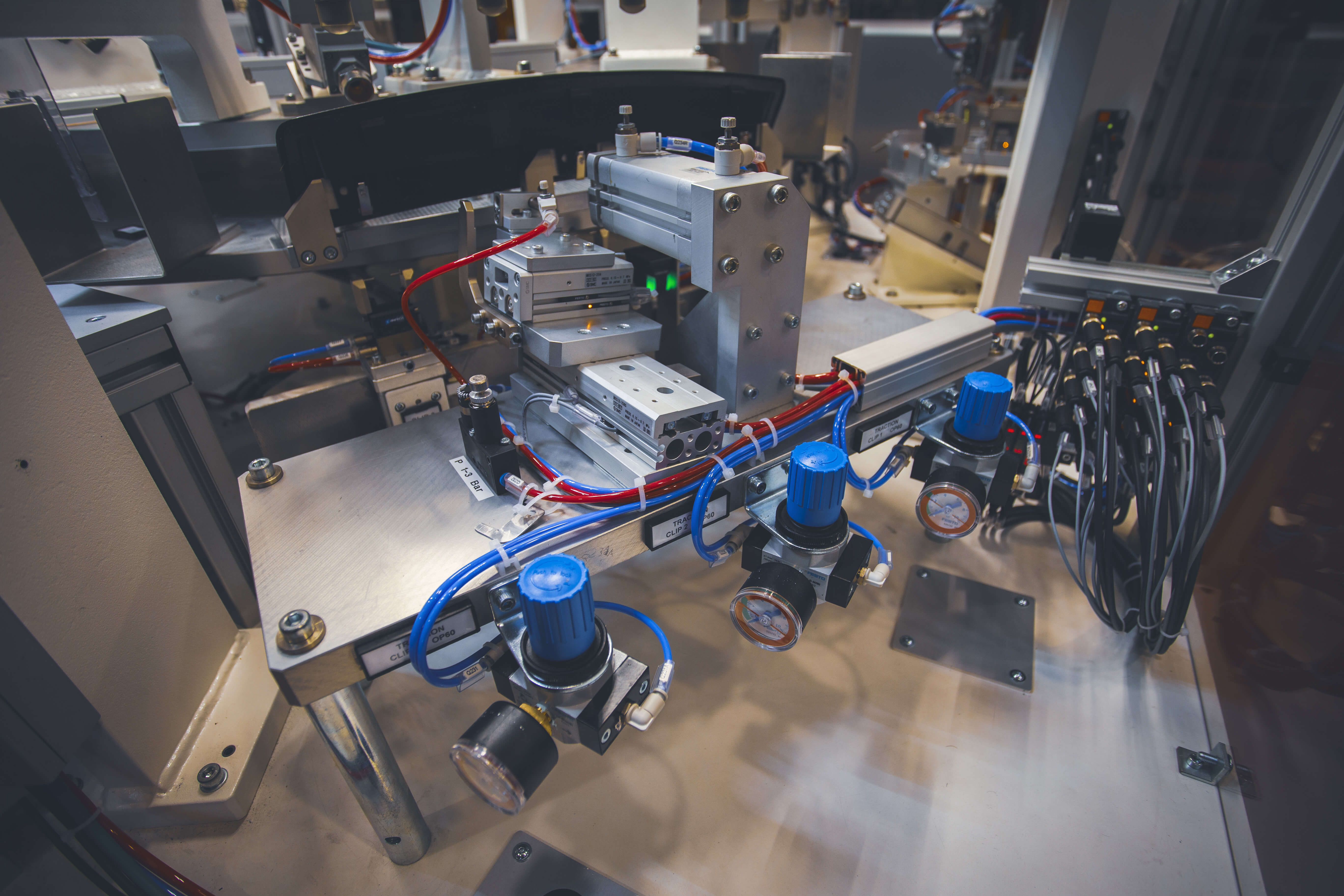

ATS carries out in-house activities for designing systems integrated into its own installations with the aim of offering a comprehensive, efficient and high-performance product.

ATS is able to design and construct systems that are perfectly integrated in the machine and optimise their operation with any kind of actuator. The system, designed with the aid of 2D CAD systems, have a unique construction layout.

ATS makes use of software design systems to offer the best user interface. Programming technicians are able to develop and manage process controllers with the main PLC manufacturers, use field bus such as DeviceNet, ControlNet, Modbus-RTU, Profibus-DP, Interbus, CANopen, AS-Interface, CC-Link, use data capture boards, develop supervision software in LabView and Visual Basic environments. Product traceability and management of production lots is guaranteed by interfacing with the Customer’s SQL Servers.

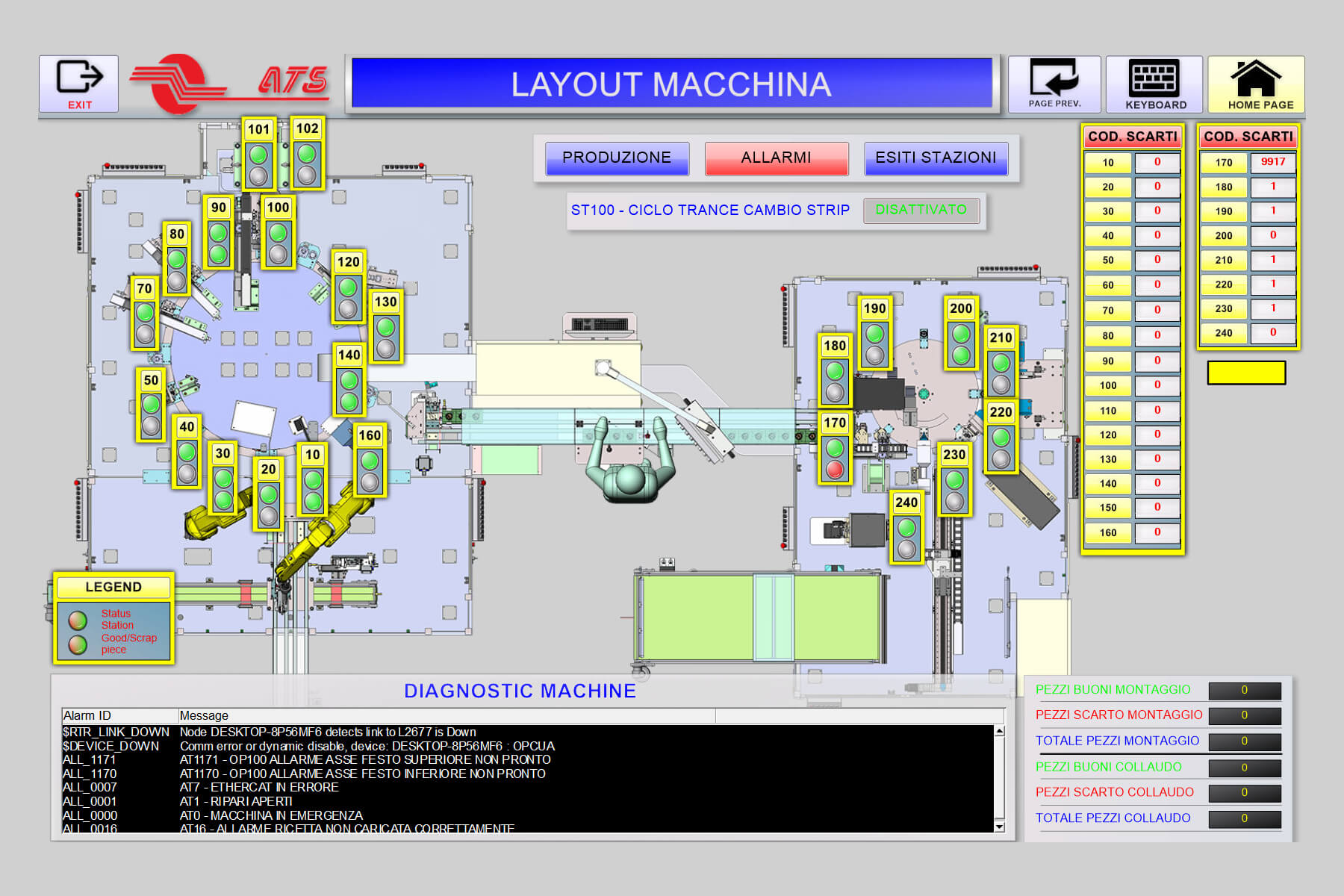

ATS develops computer systems that assure more efficient management of production processes. These industrial automation solutions include the development of a set of tools for production facilities, the so-called SCADA systems. Through this software technology it is possible to have full control over the entire production process, even remotely.

DATA SUPERVISION AND COLLECTION (Scada)

The SCADA computer system makes it possible to supervise and collect data and monitor the industrial production system. The SCADA software is able to perform complete monitoring in real time of the entire production process, even remotely.

These types of software acquire, process and file a large amount of data from the sensors distributed throughout the system. With an optimised and intuitive user interface developed by ATS, the software systems graphically show the entire production process in order to always have the essential quantities and settings under control. In the event of faults sound alarms may be received.

CONSTRUCTION, COMMISSIONING AND TESTING

ATS has production departments such as the machining workshop, precision mechanics and the machine assembly shop, and dimensional and quality checks are performed. The heart of the workshop is the CAD/CAM station with VISI Machining 3D (VERO) and VISI Wire.

The numerical control machines communicate thanks to integration of the 3D design and NC programming in exporting and importing data. This happens without errors in the data flow and no waste of time between CAD and CAM.

When assembly and wiring are completed the machine is ready for commissioning. After the programs are loaded on PLC and PC, machine testing and fine-tuning begin. At the end of this stage the machine is disassembled and sent to production. It is then ready to be tested with the Customer.

SUPPORT

After assembling the machine at the Customer’s premises, ATS assures worldwide after sale support to its products. A specific company division supports the Customer even after purchase to meet any request.

Overhauling and retrofitting

Developing new functions does not always require constructing a new machine. ATS is willing to support its customers in retrofitting its machines, to cover the following cases:

– Implementation of new stations/assembly/testing equipment on ATS lines/machines

– Reconstruction of automatic assembling and testing machines

– Electrical modifications/implementations

– Software modifications/implementations