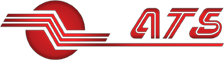

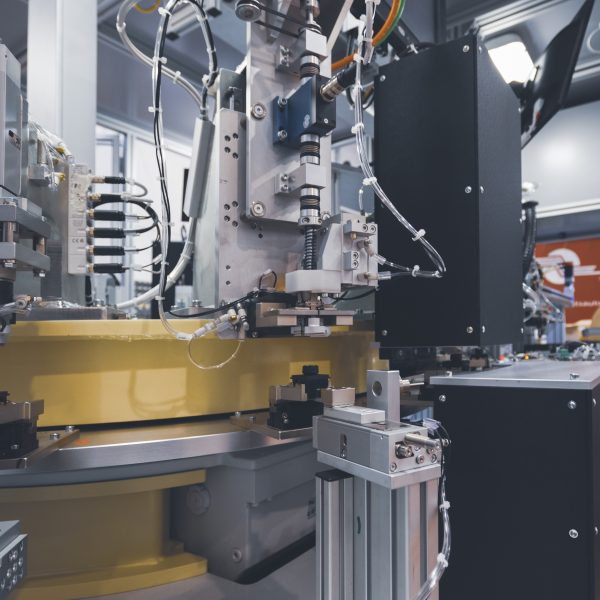

Dynamic testing

Dynamic testing is performed according to the principle of measuring the force/displacement or torsion applied by a mechanical unit to the component undergoing the test. These systems are designed and constructed by ATS for integration on automatic machines and equipment. The data acquired during testing are processed by specific SW programs (LabView environment or directly by PLC) entirely developed by ATS skilled personnel and turned into graphs/curves showing control parameters that establish the outcome of the test.

Communication between the machine’s SW and the components being tested may take place via LIN and CAN protocols.

The components for performing dynamic testing include controlled electrical axes, piezoelectric load cells and accelerometer cells with relevant signal amplifiers, position transducers, analogue modules for acquiring dynamic signals, torque meters, encoders etc.