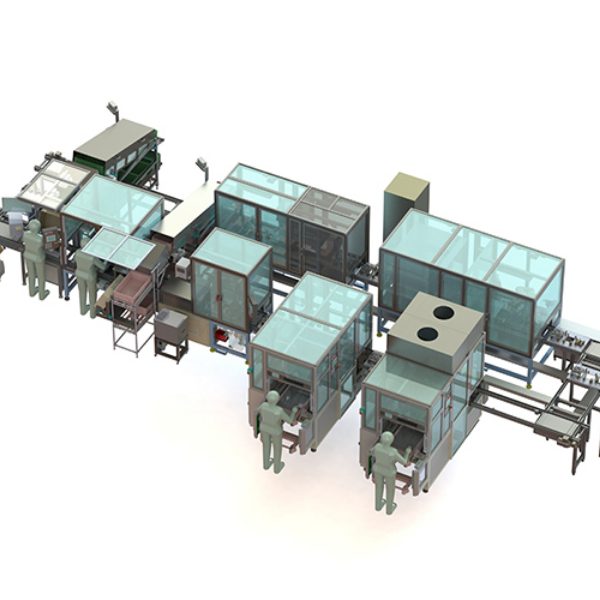

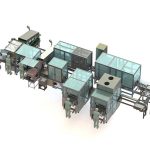

Dome Module assembly and testing line

Assembly and testing operations are performed along a pallet recirculation conveyor system with 9 stations. The system is designed for assembly and testing of the Dome Module in 7 product types, there are 6 components/subsets to be assembled. The conveyor system used is Bosch Rexroth TS2 with WT2 pallet measuring 640×400 mm.

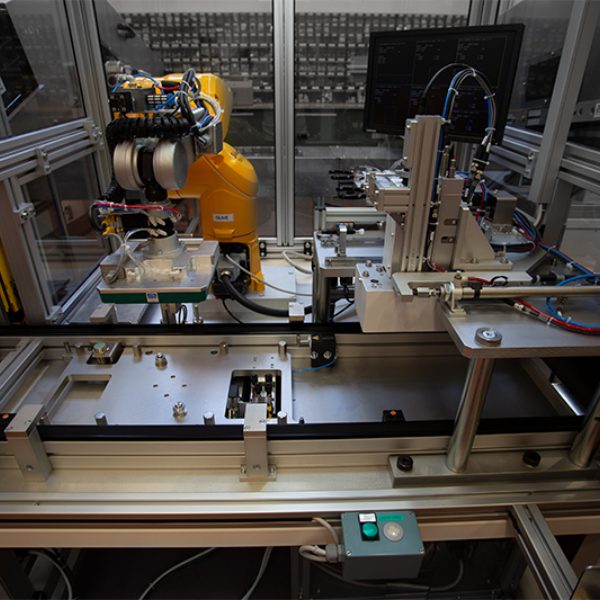

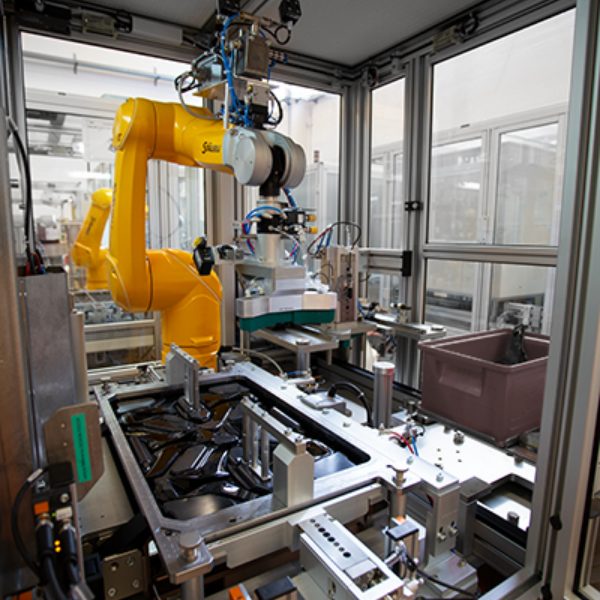

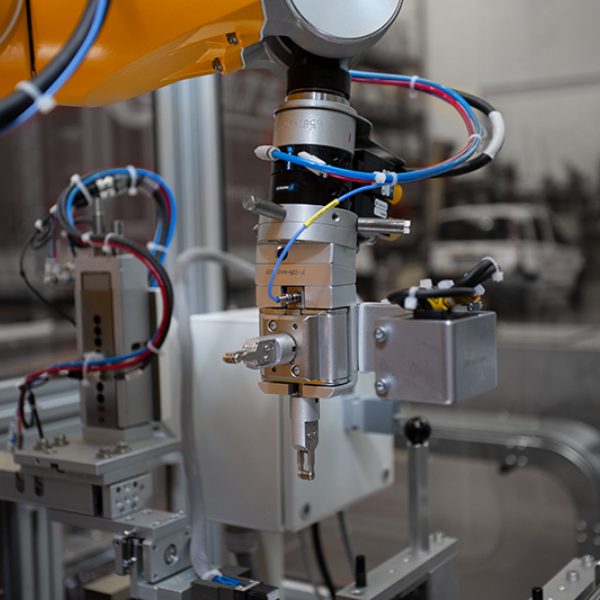

Four, 6-axis anthropomorphic robots are installed along the line, having the following specifications:

– 1 6-axis anthropomorphic robot – pay load 9 Kg, operating range 670 mm – semi-collaborative and fitted with specific gripper

– 1 6-axis anthropomorphic robot – pay load 9 Kg, operating range 670 mm – fitted with specific gripper

– 1 6-axis anthropomorphic robot – pay load 5 Kg, operating range 920 mm – fitted with specific gripper

– 1 6-axis anthropomorphic robot – pay load 9 Kg, operating range 670 mm – fitted with specific gripper

Processing takes place in lots by automatic mechanical retooling of the stations and launching the specific program from the operator interface panel.

Four, 6-axis anthropomorphic robots are installed along the line, having the following specifications:

– 1 6-axis anthropomorphic robot – pay load 9 Kg, operating range 670 mm – semi-collaborative and fitted with specific gripper

– 1 6-axis anthropomorphic robot – pay load 9 Kg, operating range 670 mm – fitted with specific gripper

– 1 6-axis anthropomorphic robot – pay load 5 Kg, operating range 920 mm – fitted with specific gripper

– 1 6-axis anthropomorphic robot – pay load 9 Kg, operating range 670 mm – fitted with specific gripper

Processing takes place in lots by automatic mechanical retooling of the stations and launching the specific program from the operator interface panel.

220 PCS/H

220 PCS/H