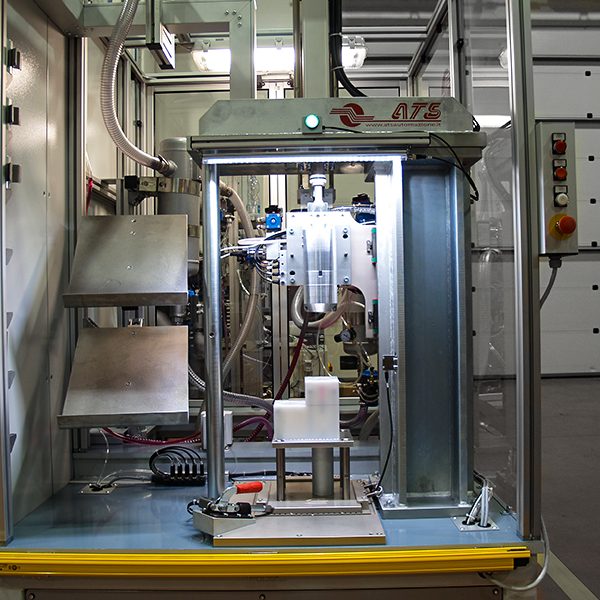

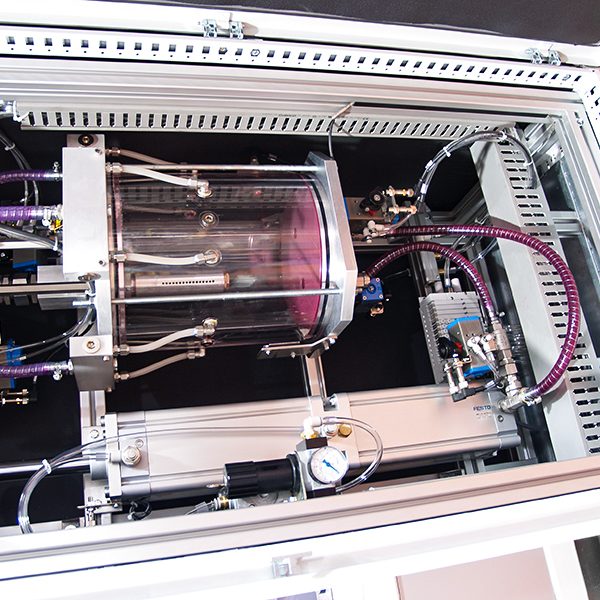

Shock Absorber Unit filling bench with Gas-Oil in vacuum

The machine is designed to fill Gas-Oil in Shock Absorber Sets for motorbikes. The Gas-Oil filling process takes place with vacuum. Seven types of shock absorbers are processed by the filling equipment, and 3 components are assembled. The oil used for filling the Shock Absorber Units undergoes a special degassing treatment (oxygen extraction) before being fed into the filling circuit.

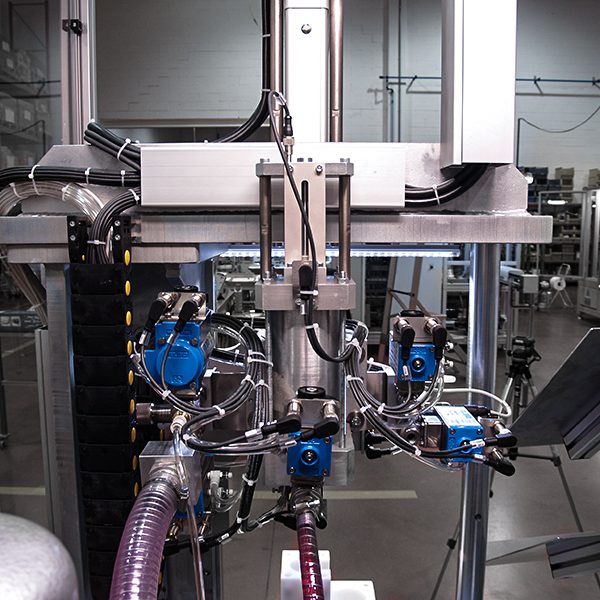

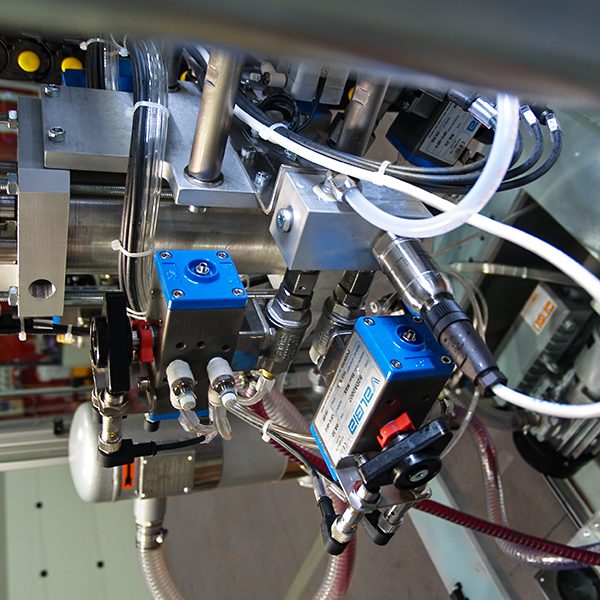

The movements required on the bench for correctly performing the filling operations of the Shock Absorber Unit are carried out by application of controlled electrical axes. The oil used for filling is controlled by a specific circuit that includes storage tanks, 40 m3 vacuum generation pump, oil drafting membrane pump, cutoff valves, oil-air separation cyclone, pressure regulators, pressure boosters, pressure transducers, volumetric batcher, heat exchanger for cooling degassing circuit compartment.

The equipment is placed on a bench constructed in electro-welded tubular structure with support plate fitted with vibration damper levelling feet. Processing takes place in lots by mechanical retooling of the equipment/holding fixtures requiring it and launching the specific program from the operator interface panel.

60 PCS/H

60 PCS/H