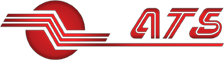

Machine for Intercooler Air Inlet Sleeve finishing process

Development of a set of equipped plates for finishing product Intercooler Air Inlet Sleeve. The whole equipment is housed on an anodised aluminium plate sized 1800×1000 mm. The product is processed in batches by inserting the memory card of the required program in the control rack which enables the fixtures on the equipment, wired in specific connectors or local junction boxes. Inside the structure is a lower conveyor belt for removing scraps and an industrial extractor.

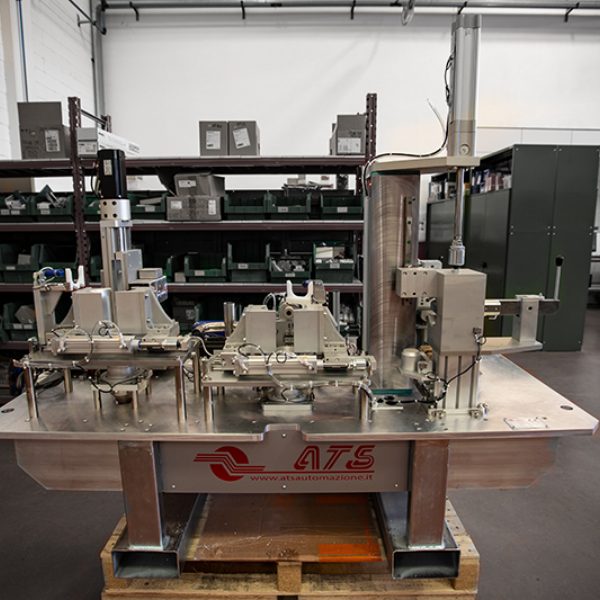

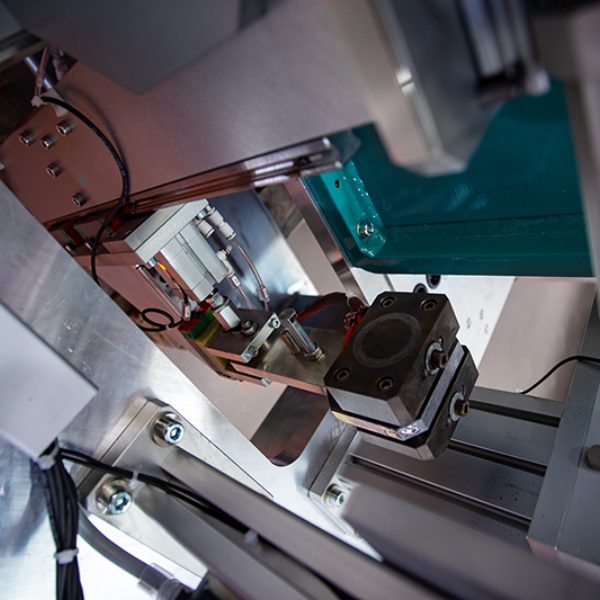

The product to be processed is placed on computer-designed holding fixtures and appropriate locks for each processing stage.

The most significant product finishing operations include:

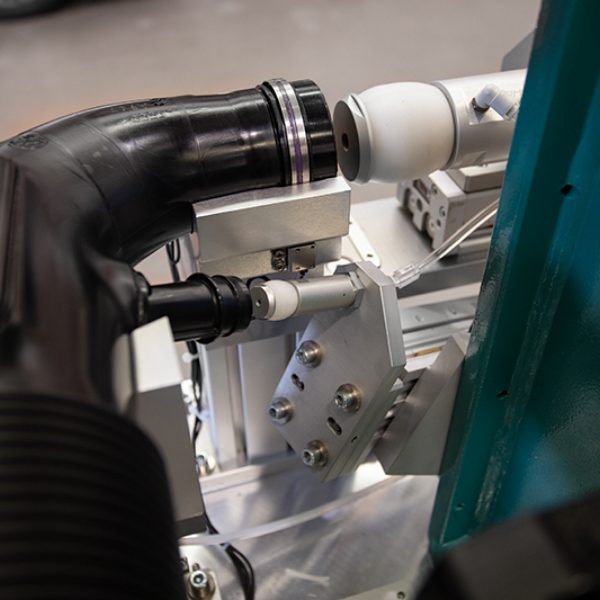

– Appendix seat milling unit with CNC Cartesian system

– Internal sleeve cleaning by blowing and extracting ionised air

– Disc milling, extraction and removal unit

– Appendix welding units on sleeve by hot plate system

– Metal strap screwing unit

– Sleeve air leak test unit at 0.1 bar

50 PCS/H (manual + automatic operations)

50 PCS/H (manual + automatic operations)