Car Light assembly and testing line

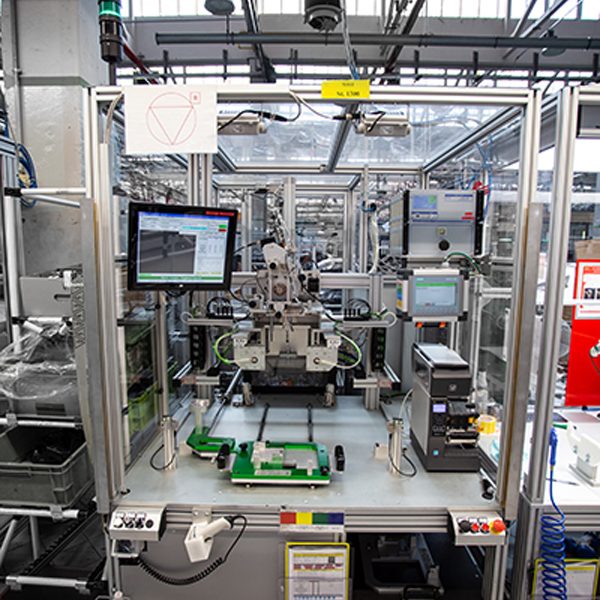

Car light assembly and testing line in the 35W (right and left) and 25W (right and left) versions. The line includes semi-automatic benches for preparing the sub-sets, final light assembly benches, robot cell for lens flaming and gluing on stg housing, photometric test and air leak test bench, for 14 operations in total. Specifically, the line consists of the following operations:

– Stg Module pre-assembly bench

– Stg DRL pre-assembly bench

– Stg Module on Stg Housing assembly bench

– Drivers on Stg Housing assembly bench

– Stg DRL + Stg Turn Indicator on Stg Housing assembly bench

– Stg Side Maker on Stg Housing assembly bench

– Stg Main Bezel pre-assembly bench

– Pre-photometry test bench

– Stg Lens pre-assembly bench

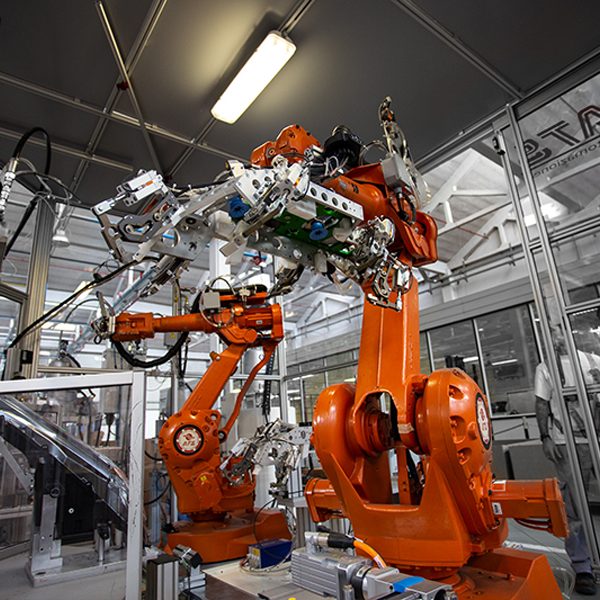

– Stg Lens on Stg Housing flaming and gluing robot cell

– Bench for completion and component presence check on Light

– Photometry and air leak test bench

– EOL lens visual inspection and protective film application bench

Two anthropomorphic robots are installed in the robot cell, having the following specifications:

– 1 6-axis anthropomorphic robot – pay load 20 Kg, operating range 1550 mm – fitted with specific gripper for handling the lens

– 1 6-axis anthropomorphic robot – pay load 20 Kg, operating range 1550 mm – fitted with double gripper (interchangeable) for forming and metering glue bead on Stg Housing

All the benches are controlled independently with their own PLC and operator interface consisting of button board with touch-screen panel.

The product traceability SW is installed on a specific PC for monitoring the line.

30 PCS/H

30 PCS/H