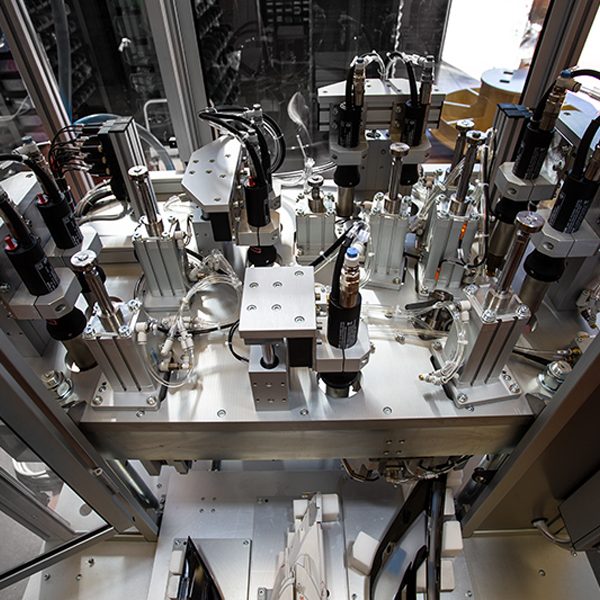

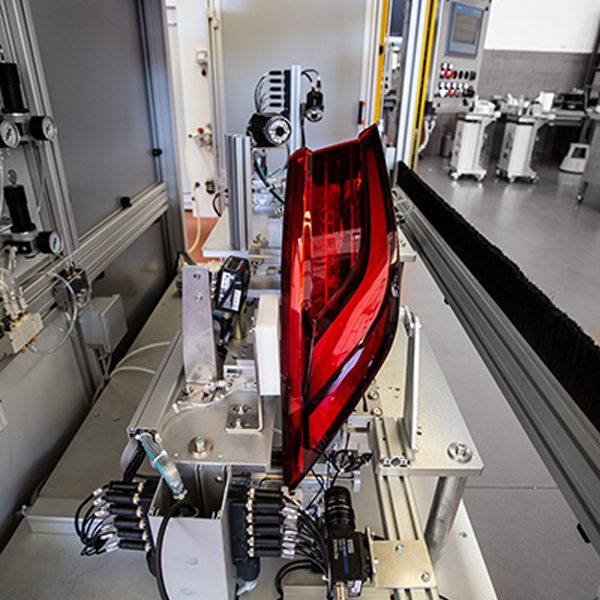

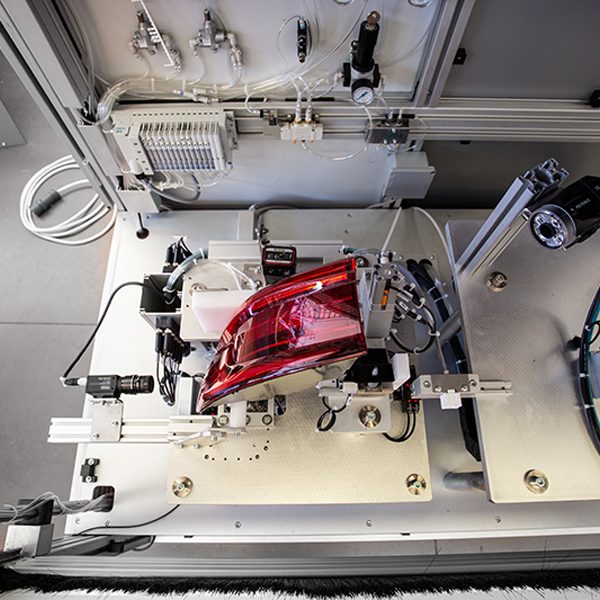

Car fixed/mobile rear lights assembly and testing line

Rear Light assembly and testing line in the Fixed (right and left) and Mobile (right and left) versions. The line is divided into 2 sets of mirroring equipment, one for processing the right Fixed/Mobile Tail lights and one for processing the left Fixed/Mobile Tail lights. The line includes manual assembly and screwing benches for preparing the sub-sets and complete lights, semi-automatic benches for welding plastic by blowing hot air, semi-automatic benches for electrical and functional testing, for a total of 8 operations. Specifically, the line consists of the following operations:

– Bezel heat welding bench on Inner Lens

– Bezel assembly bench on Reflector

– PCB assembly bench on Stg Reflector/Bezel

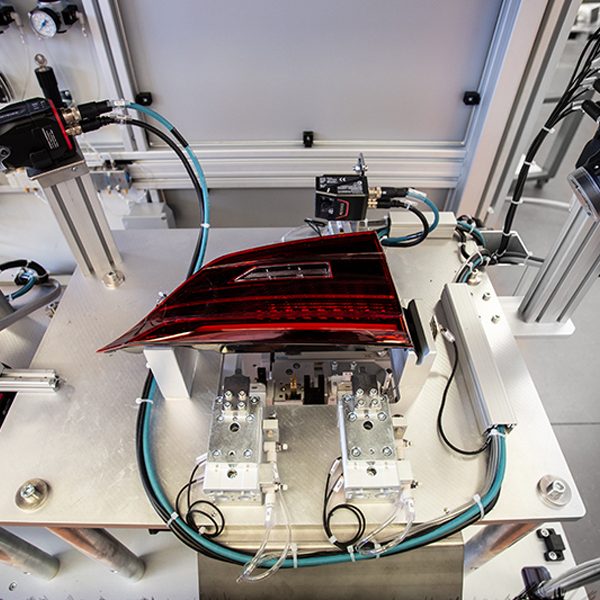

– Stg Reflector/Bezel assembly bench on Housing and pre-testing

– Final Light assembly bench with gasket and fixing pins

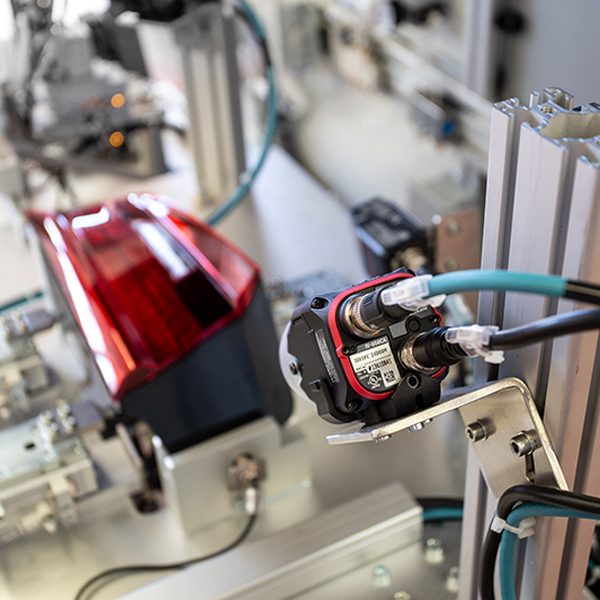

– Electrical and functional testing bench

All the benches are controlled independently with their own PLC and operator interface consisting of button board with touch-screen panel.

The product traceability SW is installed on a specific PC for monitoring the line.