Machine for inserting Contacts on Connectors (2-20 Ways)

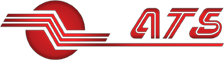

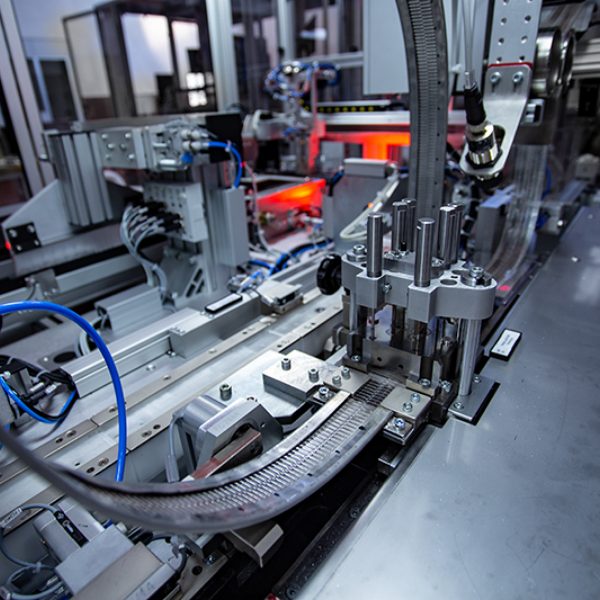

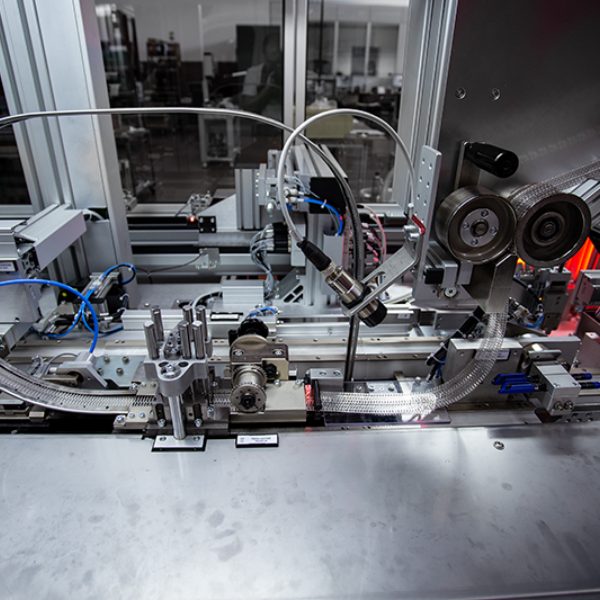

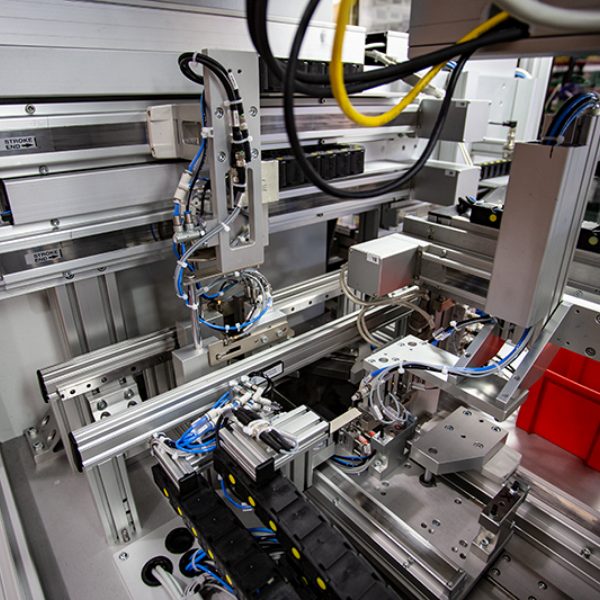

The system is designed to stamp and insert contacts from strip coils on connectors (Housing) in 20 product types, from 2 to 20 ways. The Housings are supplied in stick and are fed by a system consisting of two vertical storage units for tray build-up on infeed/outfeed connected by three double conveyor belts. The contacts are supplied in strip coil and are fed by a coil unwinder automatically controlled by the machine. The equipment is placed on a bench constructed in electro-welded tubular structure with support plate fitted with vibration damper levelling feet.

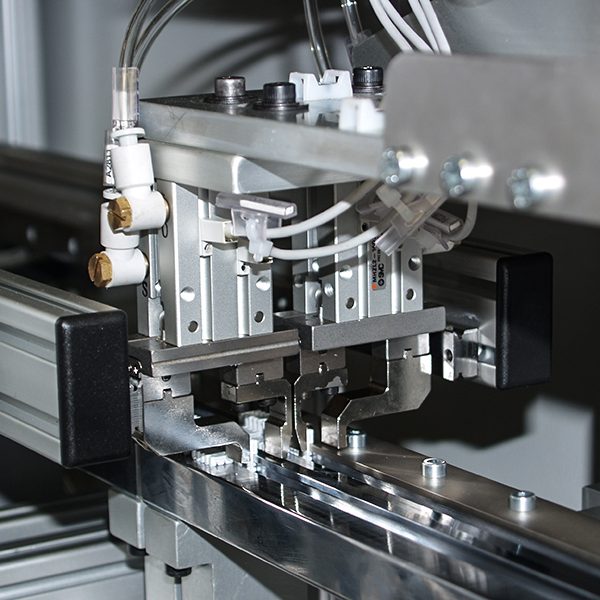

Feeding, bending, stamping and insertion of the contacts takes place through a motorised insertion head operating with mechanical cams with a progressive single step system of 1200 insertions/min. After insertion of the contacts, the sticks are separated by a special cutting unit and each single connector undergoes a presence and deformation inspection of the contacts with a specific vision system and selective elimination of waste items.

Transfer and feed of the Housing Sticks and finished Connectors between the various stations takes place by means of ad hoc conveyors driven by 20 electrical linear axes. Processing takes place in lots by automatic mechanical retooling of the stations and launching the specific program from the operator interface panel.

1200 INSERTS/MIN

1200 INSERTS/MIN